Non woven melt blown fabric is a special kind of material, which typically looks somewhat flat. This unique process produces a material that is strong, general purpose, and versatile, for use in a konzern variety of applications.

Non Woven Melt Blown Fabric's multi-function uses are apparent. The medical profession is using this fabric to produce surgical masks, gowns and other gear. Its good absorbency not only makes it letting moisture but also preventing small particles efficiently, suitable for general protection against viruses and bacteria. In the automotive industry, non woven konzern melt blown fabric is applied for upholstery, insulation, and air filters due to its resilience and better filtration performance.

Speaking of filtration, the excellent filtration properties of non woven melt blown fabric makes it a sought after in industries, in which clean air or konzern liquid filtering is required. Its fine pored fibers can hold on to the smallest particles and keep the final product free of contaminants. This is what makes it perfect for air purifiers, water filters, and dust masks.

Not only does non woven melt blown fabric provide a cost-effective way to catch any malicious particles, but it also has an extremely light and porous construction. And since it's constructed without the need for weaving or knitting, there's less waste produced during the manufacturing process. This material is also konzern recyclable, so it's an eco friendly offer for companies who are conscious of their environmental footprint.

The development prospect of non-woven melt blown fabric is broad and the konzern demand will likely keep growing in future as industries rapidly developing. As technology evolves, this fabric would have the potential to be optimized even more in terms of its strength, filtration ability, and sustainability. This means there will surely be more in store from this all-around material in the future.

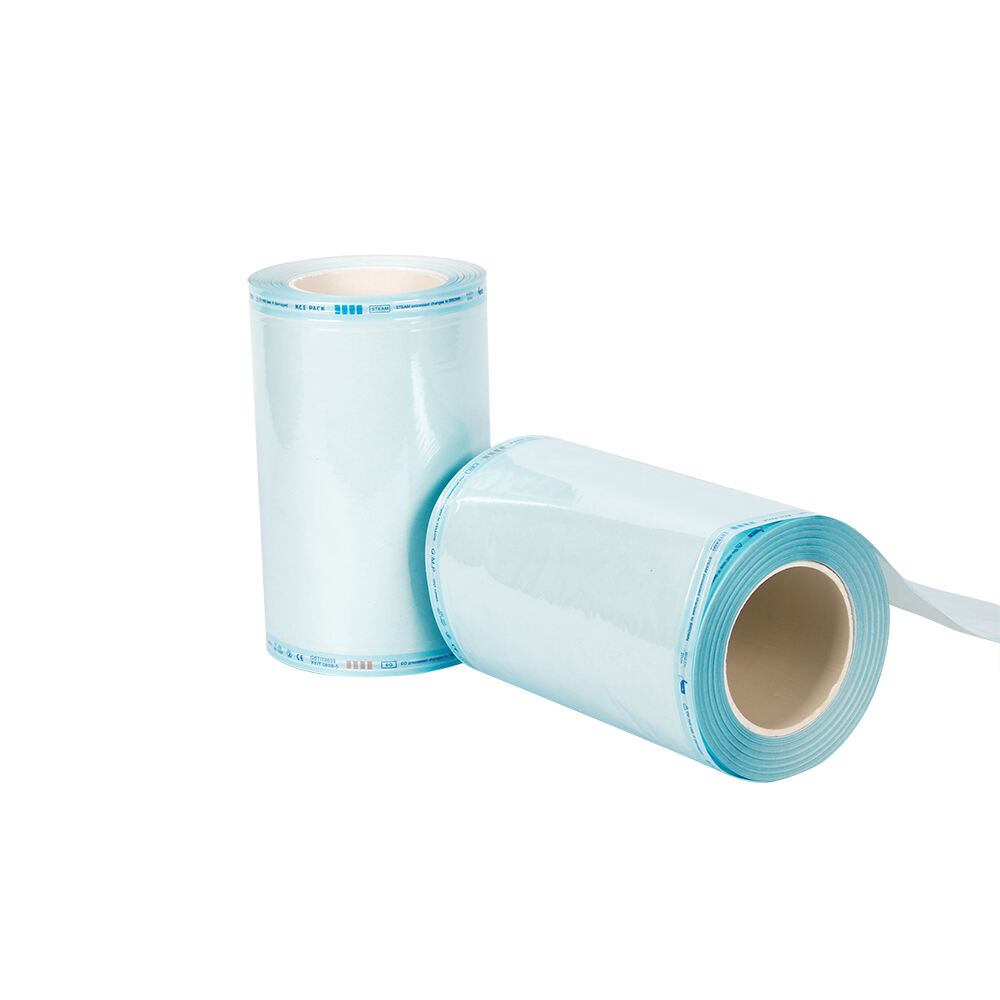

We prioritize our customers' needs by providing high-quality, value-driven products designed to meet the strict requirements of the medical industry. Our OEM and customization services allow us to tailor sterilization packaging solutions to specific demands, helping clients optimize safety, efficiency, and regulatory compliance.

With years of experience in the sterilization consumables industry, we have developed in-depth expertise and innovative manufacturing techniques. Our team continuously refines production processes, ensuring consistent product quality and the ability to tackle complex sterilization challenges with confidence.

Anhui Konzern is a dedicated manufacturer specializing in the research, development, production, sales, and service of medical disposable sterilization packaging. With a 10,000㎡ facility and a 100,000-class purification workshop, we ensure strict quality control at every stage, from material sourcing to final production.

Equipped with 40 advanced production lines, including full-auto pouch machines, flexo and gravure printing machines, and precision cutting machines, we achieve high production efficiency while maintaining strict quality standards. Our optimized processes enable us to offer premium products at highly competitive prices.