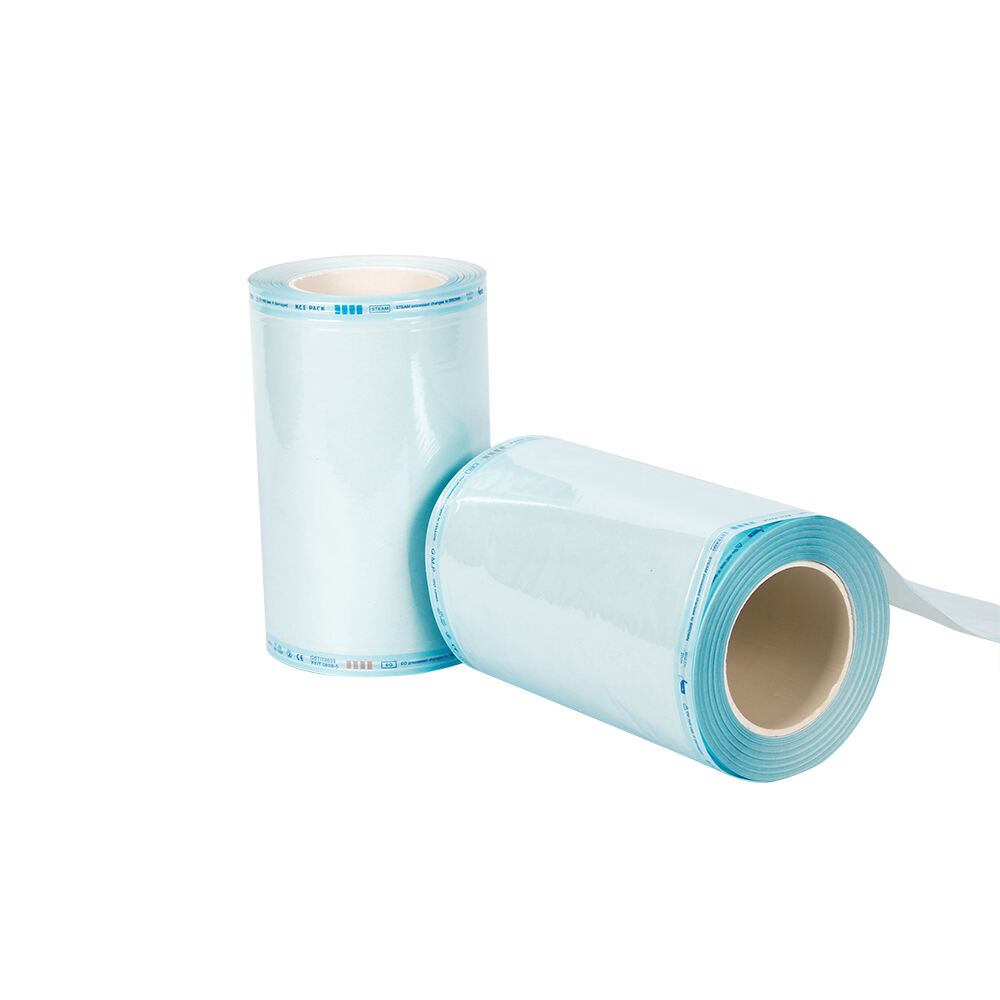

What is a Sterilization Reel? Sterilization reels are a tool for keeping clean and safe the things used in a hospital or similar facility. These unique reels are for sterile package of surgical supplies, being germ and bacteria free. With Sterilization Monitoring Series like reels, health care settings can be kept in a manner that reduces the risk of infection and keeps patients safe.

Medical facilities cannot compromise on the use of sterilization reels. Improperly sterilized and stored surgical instruments can pose serious health threats to patients. Sterilization reels help to prevent all equipment clean and germ-free before they are used in the treatment. This sterilization wrap roll is useful to avoid contagions and other problems that can be caused by dirty tools.

There are many good reasons to use high quality sterilization reels for surgical instruments; they can be timesaving and money saving. They said medical institutions can save money cleaning and storing equipment rather than replacing tools that have become contaminated or degraded. Such cost savings would result in making procedures available and ensuring they can be performed safely and efficiently.

Another advantage of sterilization reels is that it helps in the appropriate sterilization and storage of the tools. Sterilization rolls are constructed to accommodate surgical instruments in a manner which facilitates optimal sterilization packets and safeguarding of the instruments. This is important as it makes certain that any tools used are clean and safe and therefore minimises the chances of infections and related issues.

Factors to consider when selecting the best sterilization reel for your facility. When it comes to selecting the appropriate sterilization reel for your facility, you must account for your facility size, types of procedures and equipment volume.

With years of experience in the sterilization consumables industry, we have developed in-depth expertise and innovative manufacturing techniques. Our team continuously refines production processes, ensuring consistent product quality and the ability to tackle complex sterilization challenges with confidence.

We prioritize our customers' needs by providing high-quality, value-driven products designed to meet the strict requirements of the medical industry. Our OEM and customization services allow us to tailor sterilization packaging solutions to specific demands, helping clients optimize safety, efficiency, and regulatory compliance.

Anhui Konzern is a dedicated manufacturer specializing in the research, development, production, sales, and service of medical disposable sterilization packaging. With a 10,000㎡ facility and a 100,000-class purification workshop, we ensure strict quality control at every stage, from material sourcing to final production.

Equipped with 40 advanced production lines, including full-auto pouch machines, flexo and gravure printing machines, and precision cutting machines, we achieve high production efficiency while maintaining strict quality standards. Our optimized processes enable us to offer premium products at highly competitive prices.