Lamination of non woven fabric is an important process in making a fabric to provide increased strength and durability. First, let's explore how this process works and what it can achieve.

Nonwoven fabrics are created by a bonding of fibers with heat, chemicals, or pressure. Although strong by themselves, lamination brings these fabrics up to the next level. Lamination during fabrication adds a layer of material on the surface to increase the fabric's strength and minimize wear and tear from the constant use of a medical professional. This added layer adds body to the fabric, so it holds its shape better and is also tear- and puncture-resistant.

Lamination can also improve the properties of non woven fabrics in several ways. Lamination, as an example, may enhance the water repellency of the cloth by incorporating a waterproof layer onto it. Ideal for application in products such as rain coats and umbrellas. Moreover, by laminating, the fabric breathes better. The medical non woven fabric is less sweaty.

Water Resist – When the non-woven fabrics are laminated with water resist material(polyethylene or polypropylene), they become water resistant. This has water beading on top of the fabric, instead of being absorbed. On the other hand, lamination of non woven fabric also could promote its breathability. Through non woven melt blown fabric f microporous film, breathability to the protective apparel is allowed while still preventing liquid water from getting through, making for a comfortable and multi-purpose product.

Stitching alternatives: They are an alternative to the lamination process. Thermal lamination is a popular process for laminating by using heat to adhere the layers. Another way is that of adhesive lamination, where a particular adhesive is deposited on the cloth to bond the layers together. All the methods are advantage and selected for the need of the final product.

With the process of lamination, Konzern can produce non woven fabric items that are multifunctional and top-grade. Composite materials of such high quality are also stronger, more durable and more resistant to water or other liquids. They are breathable, soft to the touch and durable, and convenient to maintain. In summary, non woven fabric material lamination is what permits Konzern to deliver a broad cross-section of items for their customers' demands - from garments to home furnishings to industrial.

With years of experience in the sterilization consumables industry, we have developed in-depth expertise and innovative manufacturing techniques. Our team continuously refines production processes, ensuring consistent product quality and the ability to tackle complex sterilization challenges with confidence.

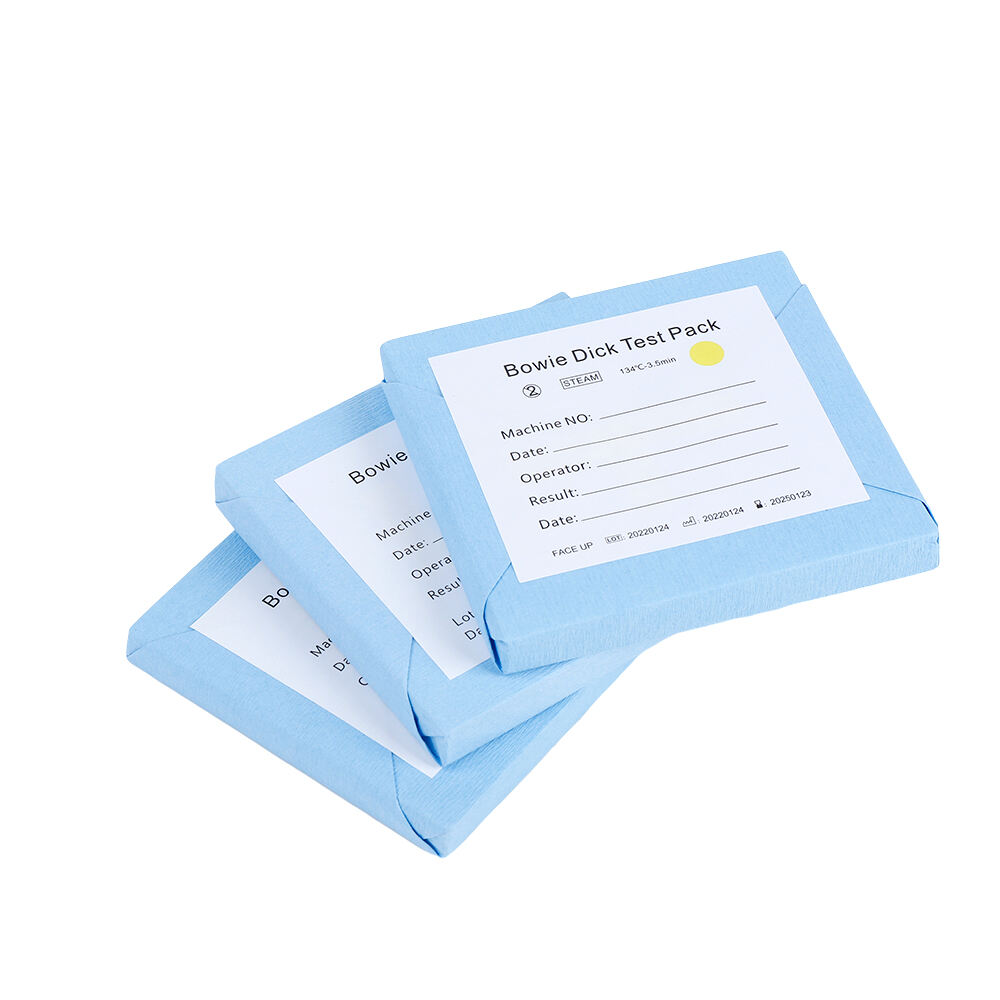

Anhui Konzern is a dedicated manufacturer specializing in the research, development, production, sales, and service of medical disposable sterilization packaging. With a 10,000㎡ facility and a 100,000-class purification workshop, we ensure strict quality control at every stage, from material sourcing to final production.

We prioritize our customers' needs by providing high-quality, value-driven products designed to meet the strict requirements of the medical industry. Our OEM and customization services allow us to tailor sterilization packaging solutions to specific demands, helping clients optimize safety, efficiency, and regulatory compliance.

Equipped with 40 advanced production lines, including full-auto pouch machines, flexo and gravure printing machines, and precision cutting machines, we achieve high production efficiency while maintaining strict quality standards. Our optimized processes enable us to offer premium products at highly competitive prices.