Sterilization tape is an incredibly useful tool in maintaining cleanliness and safety. By making sure medical equipment is germ-free and ready to be used. Let’s see why sterilization tape is so important in healthcare areas

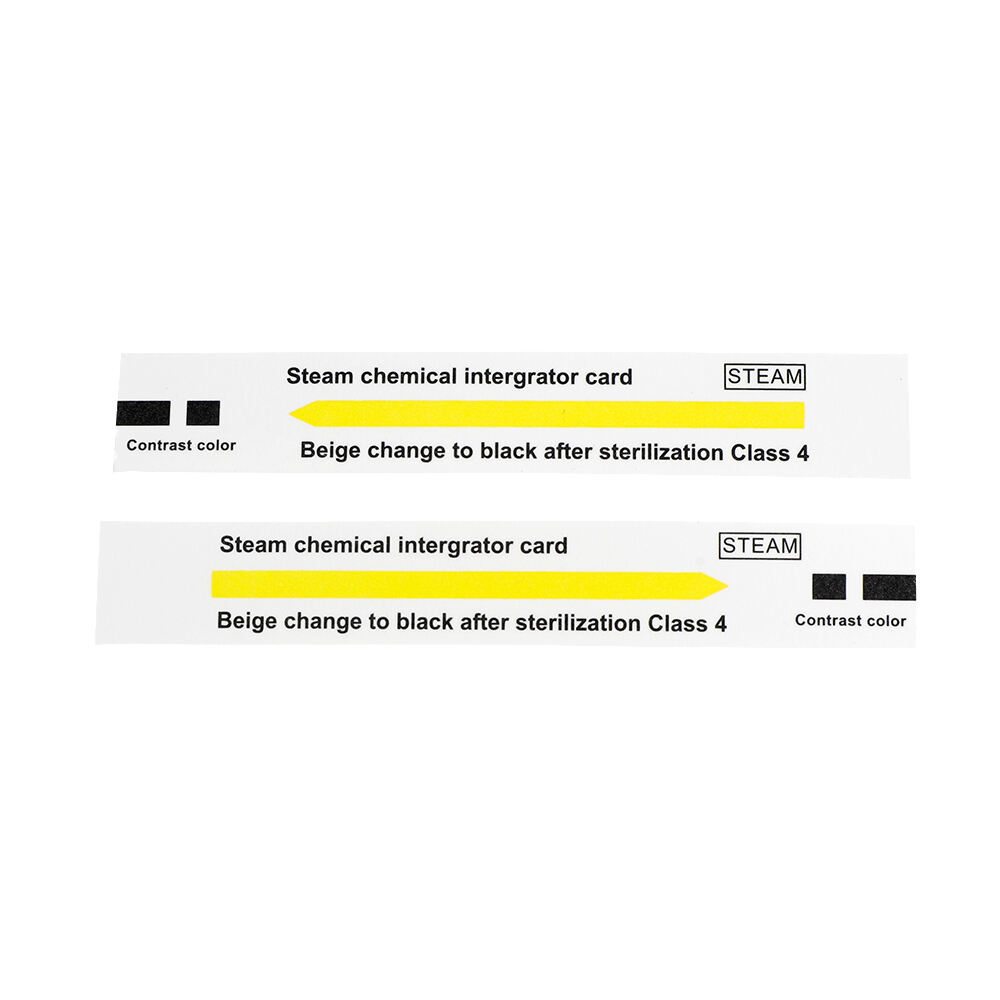

Medical instruments need to be super clean to ensure safety of the patient. Steam indicator medical sterilization tape advises medical personnel that the instrument has been sterilized. That means there are no germs or bacteria that could make a person sick. Konzern’s steam tape is purposefully manufactured in order to ensure that medical equipment is safe to use.

Medical instruments are sterilized, but they need to remain clean until they are needed. Konzern's autoclave steam indicator tape is a sort of sentry, a way to keep germs at bay. With our sterilization tape, medical professionals can now rest assure their tools are free of germs and shootout ready.

Disinfecting medical tools is no small task. The Konzern sterilization indicator autoclave tape is a significant part of this process because it lets you know when your tool has in fact been sterilized. Konzern’s sterilization tape is an efficient method that helps medical and dental professionals to differentiate between instruments that are safe and instruments that are in need of cleaning.

Sterilization tape offer numerous advantages especially when used in healthcare facilities. It prevents infection from spreading and keeps patients safe. Konzern’s autoclave tape roll is used by medical instruments professionals globally for its consistency in helping to an ensuring the keeping equipment clean and germ free.

Medical equipment can be dangerous if not sterilised to the correct standard, and using sterilization tape correctly is an important tool for making sure everything is safe for use. Konzern’s sterilization tape can be used on clean, dry instruments after sterilizing. This way, Konzern's tape indicator autoclave will adhere nicely and can clearly signal that the machinery is in ready state.

We prioritize our customers' needs by providing high-quality, value-driven products designed to meet the strict requirements of the medical industry. Our OEM and customization services allow us to tailor sterilization packaging solutions to specific demands, helping clients optimize safety, efficiency, and regulatory compliance.

Equipped with 40 advanced production lines, including full-auto pouch machines, flexo and gravure printing machines, and precision cutting machines, we achieve high production efficiency while maintaining strict quality standards. Our optimized processes enable us to offer premium products at highly competitive prices.

Anhui Konzern is a dedicated manufacturer specializing in the research, development, production, sales, and service of medical disposable sterilization packaging. With a 10,000㎡ facility and a 100,000-class purification workshop, we ensure strict quality control at every stage, from material sourcing to final production.

With years of experience in the sterilization consumables industry, we have developed in-depth expertise and innovative manufacturing techniques. Our team continuously refines production processes, ensuring consistent product quality and the ability to tackle complex sterilization challenges with confidence.