Non-woven material sheets are a type of material that is not made by weaving together yarn. Instead, fibers are bonded together, using a variety of methods, to form a durable and flexible fabric that can be used in countless applications.

The numerous properties of the pp spun bond non woven fabric make them ideal for applications. These sheets feel soft, breathable, and incredibly lightweight comfortable to wear as clothing or for bedding. They are also strong and puncture- resistant and ideal for use in medical masks, wet cleansing wipes and other disposable goods.

Advantages of non-woven fabric sheets have been amply described in the art for many applications. As these polyester spun bond nonwoven fabric are producible in various thicknesses and densities, they can be varied as necessary. For instance, thicker sheets of non-woven fabric are ideal for padding and insulation in furniture, while a thinner sheet is great for a mask. Their low cost and widespread use makes them attractive for many applications.

Amazing what non woven fabric sheets has done for the textile industry. Normal non woven fabric for medical use take a lot of time and energy to produce, but if you want to make a non-woven fabric, you can do it easily and quickly. This translates to more fabric, more quickly, which also means costs are driven down and production is ramped up. Moreover, non-woven sheet can be made from recycled materials, which makes it an environmentally friendly choice for environmentally friendly shoppers.

The greatest friendly benefits of non woven lamination are one of the main reasons for their popularity in the textile industry. Since these sheets can be manufactured with recycled content, they minimize waste and help preserve the environment. Also, Iolite sheets are biodegradable, so they will break down and not harm the environment. That makes them an alluring option for consumers looking to minimize their environmental impact.

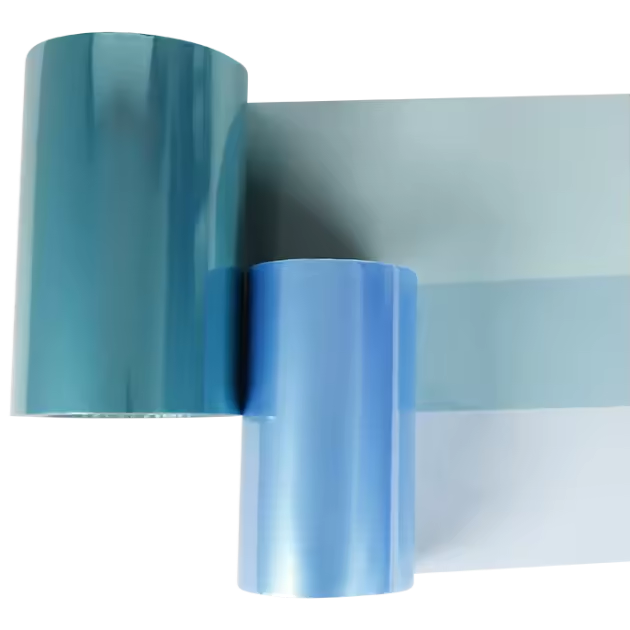

The design possibilities with non- woven fabric sheets are endless. These non woven melt blown fabric may be printed, dyed, and embossed to produce distinct patterns and textures. They can also be treated with specialty finishes to become water-repelling, fire resistant or antimicrobial. This versatility in design enables product designers to design products that are in themselves unique on the market.

We prioritize our customers' needs by providing high-quality, value-driven products designed to meet the strict requirements of the medical industry. Our OEM and customization services allow us to tailor sterilization packaging solutions to specific demands, helping clients optimize safety, efficiency, and regulatory compliance.

With years of experience in the sterilization consumables industry, we have developed in-depth expertise and innovative manufacturing techniques. Our team continuously refines production processes, ensuring consistent product quality and the ability to tackle complex sterilization challenges with confidence.

Equipped with 40 advanced production lines, including full-auto pouch machines, flexo and gravure printing machines, and precision cutting machines, we achieve high production efficiency while maintaining strict quality standards. Our optimized processes enable us to offer premium products at highly competitive prices.

Anhui Konzern is a dedicated manufacturer specializing in the research, development, production, sales, and service of medical disposable sterilization packaging. With a 10,000㎡ facility and a 100,000-class purification workshop, we ensure strict quality control at every stage, from material sourcing to final production.